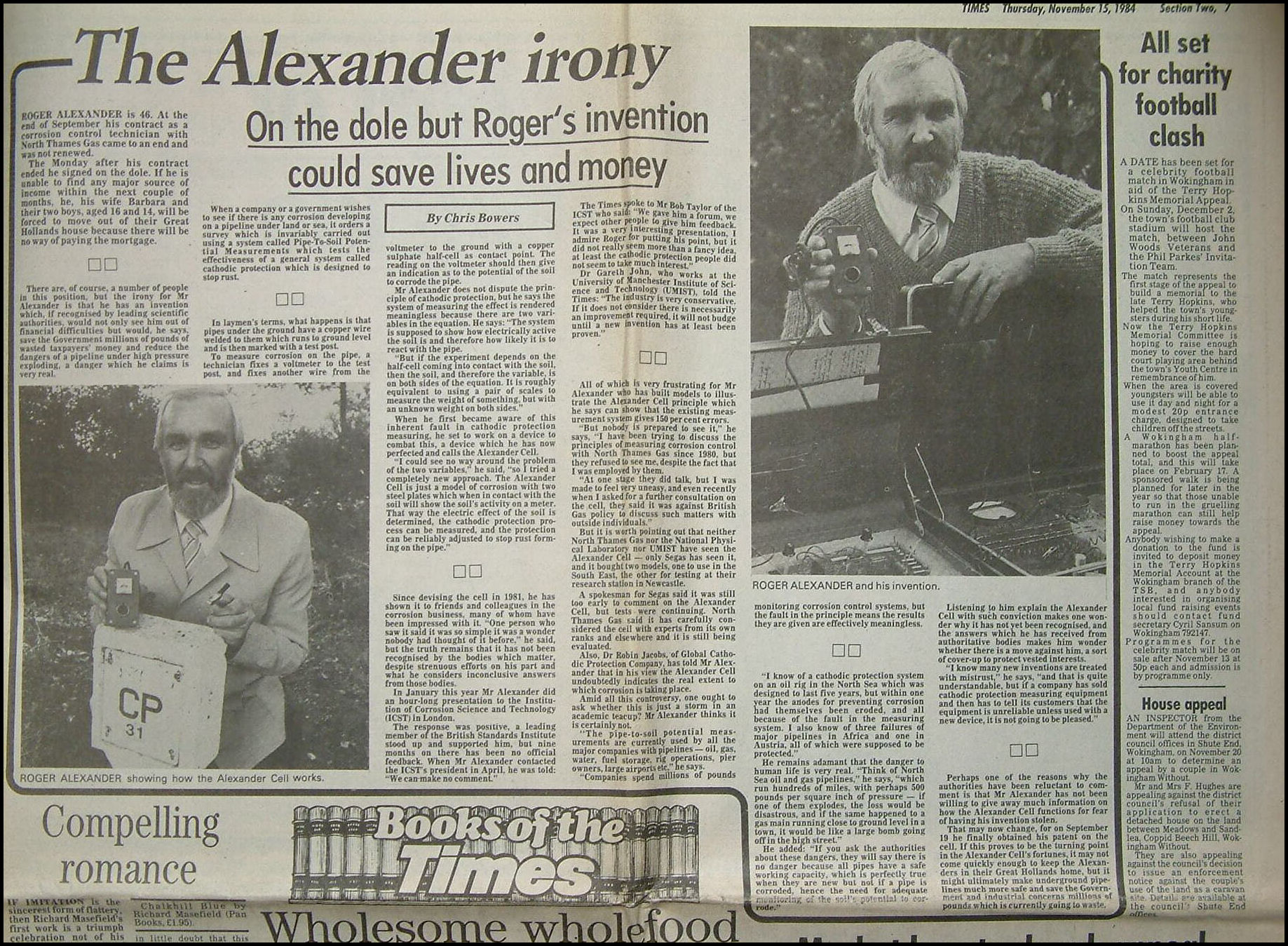

Name & Registered Office:

CATHODIC PROTECTION NETWORK INTERNATIONAL

74 DALCROSS

BRACKNELL

BERKSHIRE

RG12 0UL

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

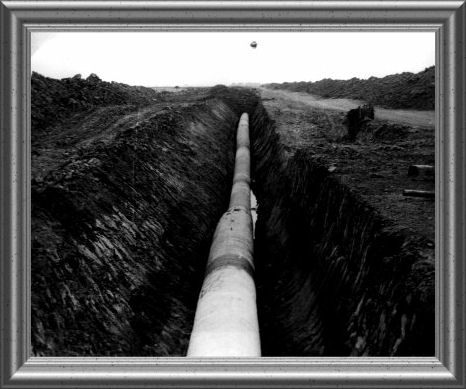

Pipelines in Nigeria when I arrived in 1975

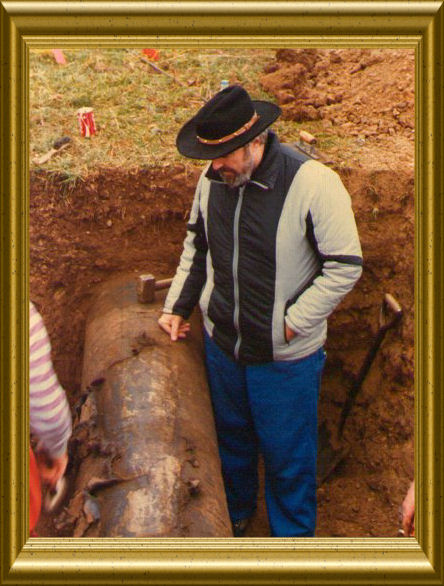

Me looking at coating damage I detected using DCVG in 1976

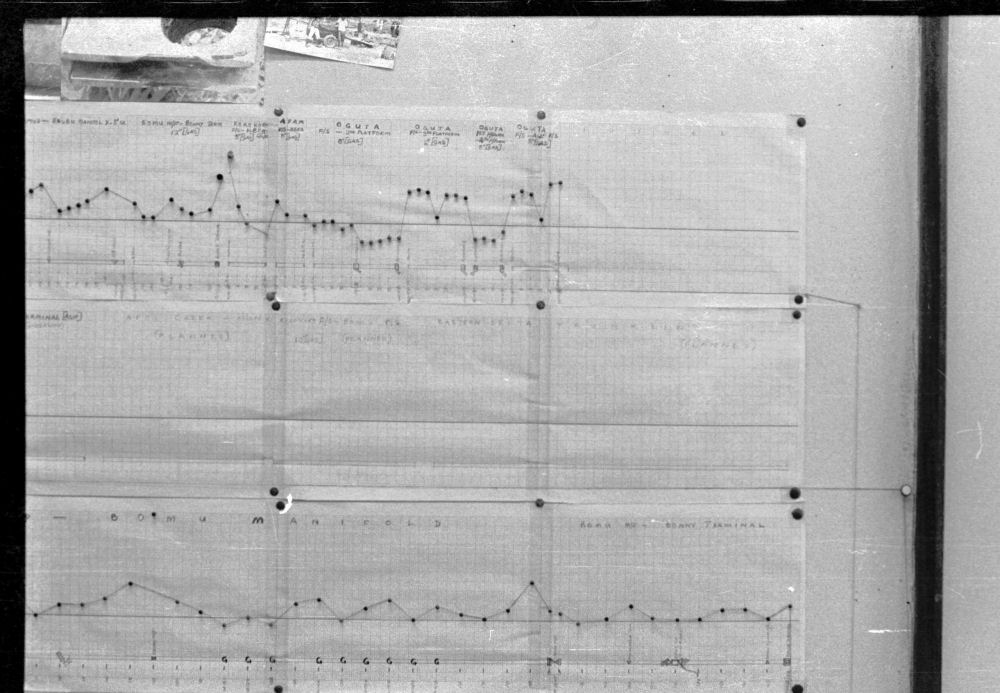

Correct predictions of corrosion and coating faults diagnosed in 1975

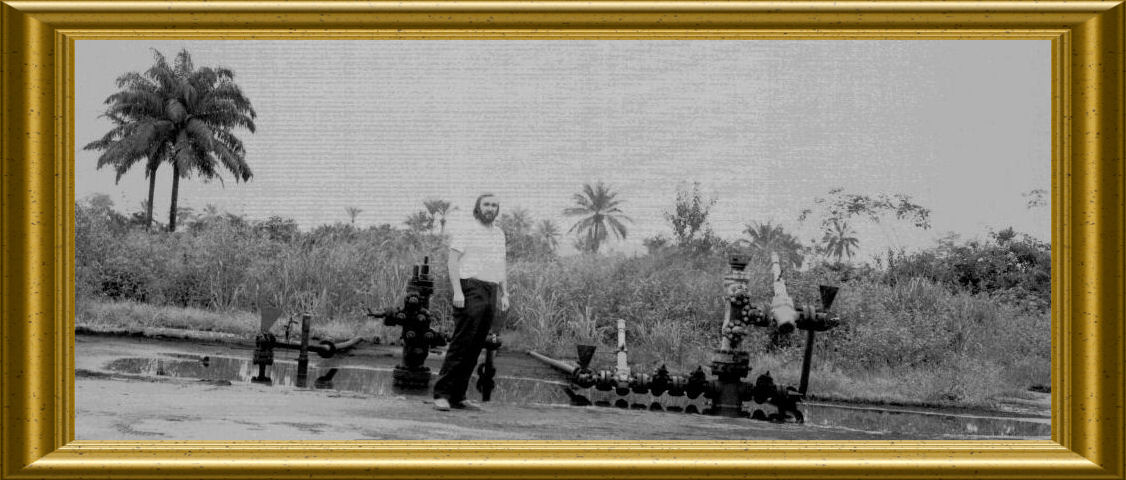

This is the manifold where I developed DCVG in 1975.

This is me standing by a Xmas tree in agriculteral land in Nigeria in the 1970's

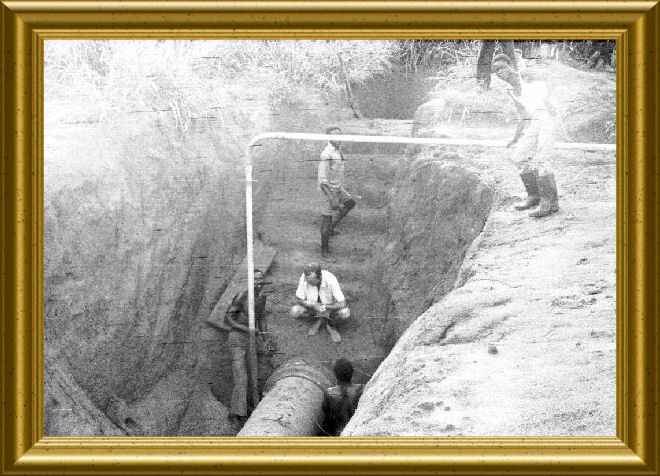

This is an excavation that I found in progress when I arrived in Nigeria

This is typical of the work that I inherited when taking over the corrosion engineering section,

This work was dangerous and ineffective.

This is work that I was in charge of, carried out very efficiently and effectively by Chima and his company to remedy a serious corrosion thread to the major trunk pipeline.

A sleeve crossing had shorted out and I detected that there was a coating fault within the anulus that could have caused a leak in the main pipeline.

Corrosion damage detected using DCVG, CIPS and the Alexander Cell.

A flowstation to which the oil is gathered from the wells before traveling through delivery pipelines to a manifold on the main trunk pipeline.

Pipeline under construction in the late 1960's in the UK.

Photograph taken hanging out of an open door of a helicopter over a swamp rig in the 1970's

Me and a Xmast tree..... note the security fence is securing some local chickens a few hundred meters away...... their need is greater.

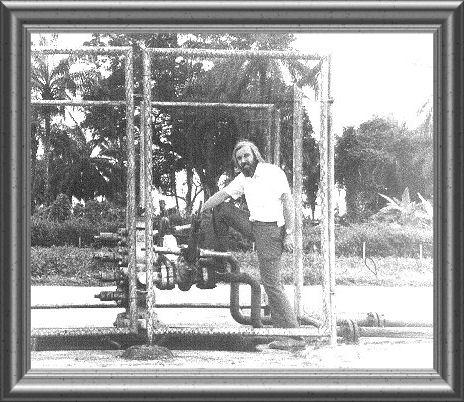

Me showing off as usual at a sleeved crossing that was filled with epoxy resin supplied by Dowell-Schlumberger as we could not remove the short cicuit at this particular location.

No further comment

The guys on the truck did all the work but I did the posing.

Sometimes I had to work

While others watched

My friend Chima, one of the best engineers I have ever known.

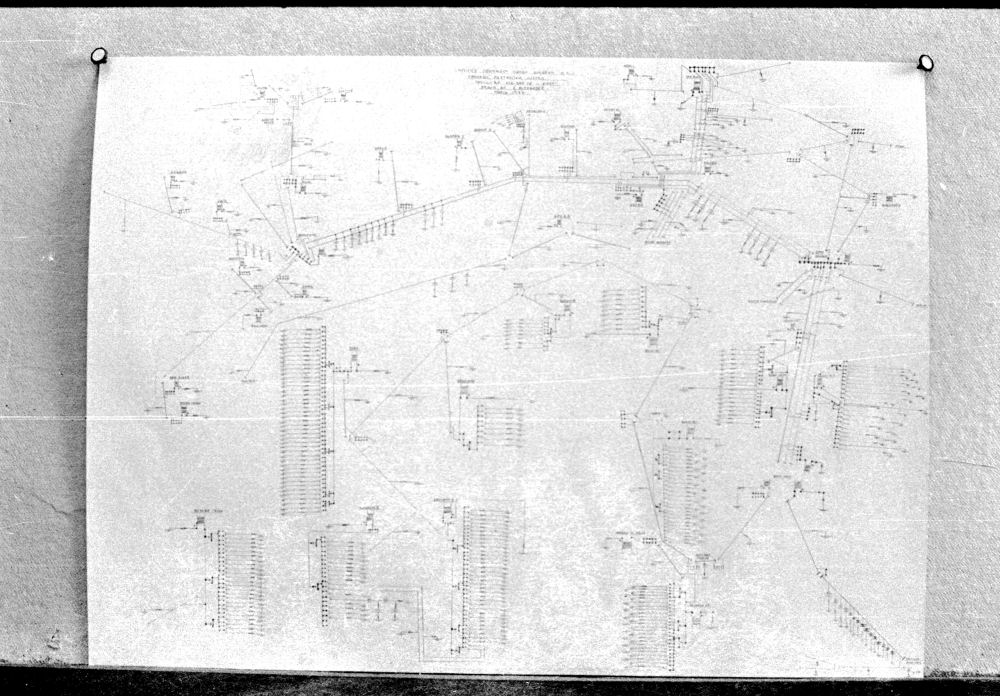

This is a circuit diagram of the network of pipelines under cathodic protection in the Eastern Division of Shell-BP Development Corporation of Nigeria.

Before computer spread sheets I designed a way of displaying a dynamic moving graph of voltage measurements to diagnose the spread of charges within our network of pipelines, facilities and transformer rectifiers.

A workover rig.

A very small part of the mess I inherited.

A neglected riser.

This probably secured the cash flow of Nigeria until today.

What a team, Chima and Dwunomwi Abidiak.

Back in the UK I find coating fault using DCVG in 1980.

Construction of Guararema Training and Research Centre, SP, Brazil