Cathodic Protection Network

Case Study 1

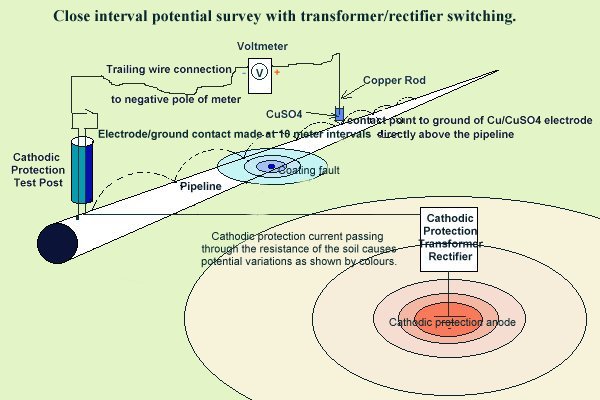

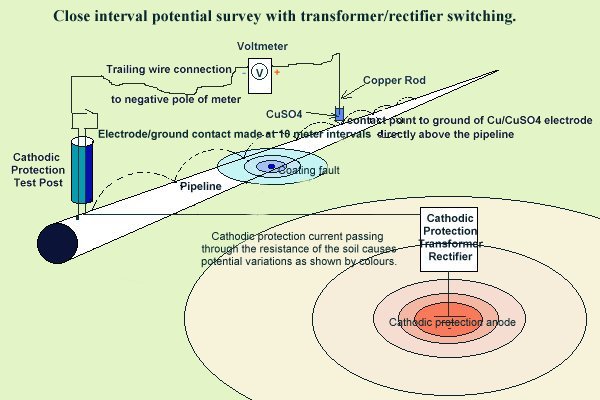

Whilst working for Atkins Inspection, on a contract to North Thames Gas, I was part of a team carrying out and developing the original CIPS type survey. This was the fourth version of the Over Line Inspection survey and was known as OLI4

.

Mike Foskett was the engineer in charge and he allowed me to develop my own technology (in my own time) on the wayleaves of the pipelines which the survey covered.

I submitted my report as required for the job and additionally reported on the progress of my own technology.

The North Thames Gas specified survey had revealed that there was a coating fault and associated corrosion at a location known as Taplow Rail Crossing. (This is sufficient information for the present operators of that pipeline to be able to identify the exact site but not enough for any member of the public to do so. This comment incase there are allegations of breach of confidentiality or security)

The basis for their diagnosis was that the voltage readings were 30% below the criterion required by BSI Code of Practice CP1021 and that corrosion would be found on exposure of the pipe.

Using my own techniques including (with permission) the Alexander Cell, I predicted the exact position and extent of the coating fault but that there would be no corrosion in spite of the very agressive nature of the backfill. This position was 2 meters from the edge of the excavation which resulted from the North Thames Gas survey.

I was appointed to inspect the excavation as it progressed using the location determined by North Thames Gas. It was large, deep and costly revealing nothing. I was asked to show the forman the exact location of the coating fault and that entailed extending the excavation by two metres. This extension revealed exactly what I had predicted and was reported widely within the Gas Corporation (which was the name of the organisation responsible at the time). The total cost of this excavation was over £40k.

As a result of this success I was given the task of investigating several other locations which can be cited in detail.

Details of the techniques that I used during these investigations can be acquired during study of the Cathodic Protection Network Training Course.

Students of this course will receive 'Accreditation' and will not make the mistakes that led to the waste of £40,000 at this location.

They will also be able to detect and prevent corrosion at coating faults where the cathodic protection is not effective.