International Cathodic Protection Training Centre

and Research Facility

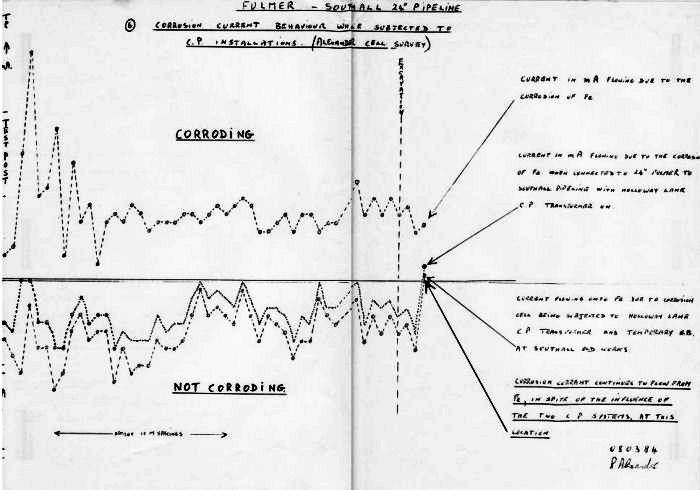

Pipeline corrosion failures have made it clear for many years that following the present codes of practice and adhering to the recommended criteria does not guarantee that corrosion has stopped.

It has long been recognised that there are inherent errors in the pipe-to-soil voltage measurements that are used in cathodic protection monitoring.

Attempts to eliminate some of these errors are made by switching the CP current off, and making the voltage measurement during the period of decay. This is done in a laboratory using a recording voltmeter or fine data-logger. This cannot be done effectively in the field unless a pH value is measured at the interface between the pipeline metal and the electrolyte.

The use of satelite synchronisation of interruptors became fashionable amongst those who thought the problem was due to the integrated nature of cathodic protection systems on networks of pipelines.

The reality is that we must make the voltage measurement at the interface between the metal and the electrolyte or it has no value in scientific theory and cannot be used to determine if the cathodic protection has stopped corrosion.

Scientists now recommend an electrode system similar to that used in the laboratory to establish the values necessary in the Nerst Equations that rely on such theories as Gibbs free energy etc. The Alexander Cell is such an electrode system and has been extensively used in field trial over many years with complete success.

Following the presentation of the paper 'A definitive Criterion For Cathodic Protection' at the ABRACO conference in Brazil, Engeduto engaged the advice of the Cathodic Protection Network to construct a Training Centre suitable to carry out research, development and training in order to provide reliable and consistent data from cathodic protection surveys.

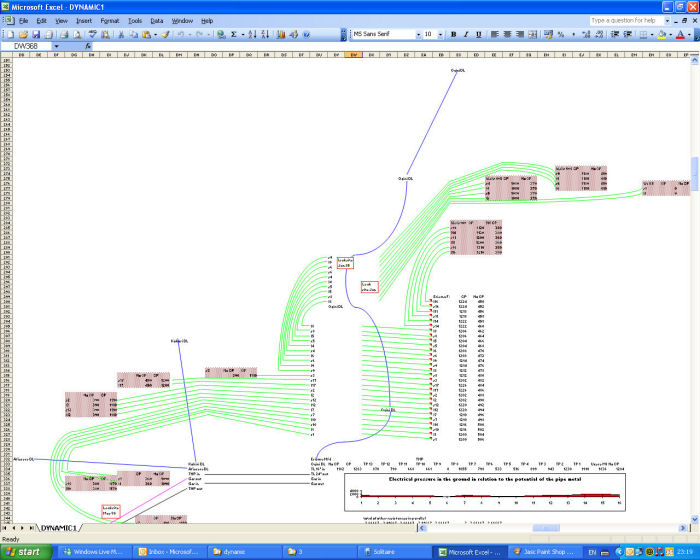

With the development of computer power, the short term measurement of the effectiveness of cathodic protection no longer presents a problem. We can now gather enough data to calculate the corrosion status of any part of a pipeline system.

Experienced CIPS and DCVG surveyors know that these surveys do not yield results that tell if the pipeline is corroding.

Engeduto and CPN are addressing this problem by training operatives the strict formal procedures that have been found to yield reliable scientific data. These enhanced DCVG and CIPS surveys include all the good practice that has been developed over the years as well as techniques that yield corrected data to satisfy the scientific and academic demands.

The training facility has pipelines specially constructed to

incorporate most of the difficult features that are experienced

when gathering cathodic protection data.

It has both impressed current and sacrificial anode cathodic protection systems that can be combined into a variety

of hybrid configurations to simulate interference and most known

disturbances that cause errors in cathodic protection measurements.

The impressed current groundbed can be used to create massive

over-protection for the study of cathodic disbondment and

hydrogen embrittlement. The ground-bed consists of three vertically set titanium anodes

that can be switched in and out of the circuit to train

students to produce a meaningful groundbed

potential profile.

A 3 meter x 2" dia pipeline coated with coal tar enamel is buried

1 meter from anode 3 and is used to demonstrate interference,

shielding, accelerated corrosion, cathodic disbondment

and hydrogen embrittlement.

It can be directly connected to a 6 meter long x 2" dia pipeline

coated with coal tar enamel that is buried parallel to the main pipeline

to show the effects of positive conductance and accelerated corrosion.

This second pipeline can also be used to show the effects of

foreign pipeline shielding.

The Main pipeline is 50 meters of 2" dia pipeline having a total resistance of 0.186 ohms

and this allows it to represent a significant length of larger

diameter, thicker walled pipeline.

It is coated with Raychem shrink wrap for the first 24.4 meters

Tapecoat for the next 23.6 meters

and coal tar enamel for the rest.

The trench has a variety of backfills starting with selected sand for the first 14 meters

grass and organic topsoil 14-18 meters.

broken concrete 18-24.5 meters,

rubbish 24.5-31 meters,

soil 31-36 meters,

grey sand 36-41 meters

granite and chips 41-47 meters

and all remaining lengths of pipeline with native spoil.

The pipelines have been constructed in the same way as major

pipelines so that students have photographs available to

support the part of the training

relating to coating,

stringing,

butt-weld coating,

ditching,

test point construction

and re-instatement.

All of these have great relevance to cathodic protection monitoring and maintenance.

The main pipeline has a water crossing that allows both fresh

and salt water to be used and can be isolated from remote earth

or be part of it. One part of the pipeline can be subject to

sulphate reducing bacteria and other parts have a variety of pH values.

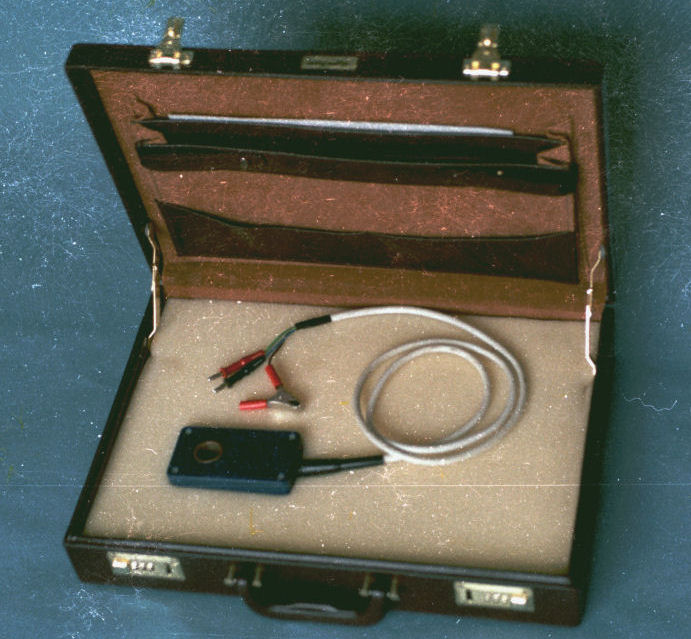

The students will have the full scope of survey instruments to use

as well as the Alexander Cell and the Isopotential cell.

The students will be instructed in all the background theory and historical development of the science and engineering practice for the past 40 years.

They will have original documentation to study relating to the development of the very first CIPS and DCVG surveys in the world.

The center has a full suite of equivalent circuits and demonstration models that the students are required to work on and understand.

The center will be used in the development of the

first cathodic protection software that uses computerised

circuit analysis to calculate when corrosion has stopped.

Students will shown the manufacture of 'half-cells' and Isopotential cells in order to explain that these are simple tools that have no mysterious qualities or capabilities.

At the top level, the centre will be used to enhance seminars that explain the massive step forward that has been made in the science and engineering practice of cathodic protection.

At the scientific level it will be used for research and development of processes and new techniques such as the utilisation of the studies into corrosion noise in electronic corrosion control in splash zones.

At the engineering level it will be used to update practicing senior corrosion engineers in the latest developments and procedures.

At the field engineer level it will be used to train in new proceedures and update older procedures to ensure they can recognise and overcome difficult field circumstances.

At the survey operative level it will be used to train them into the strict discipline required to gather reliable data.